or Call : 00961 1 880666/333

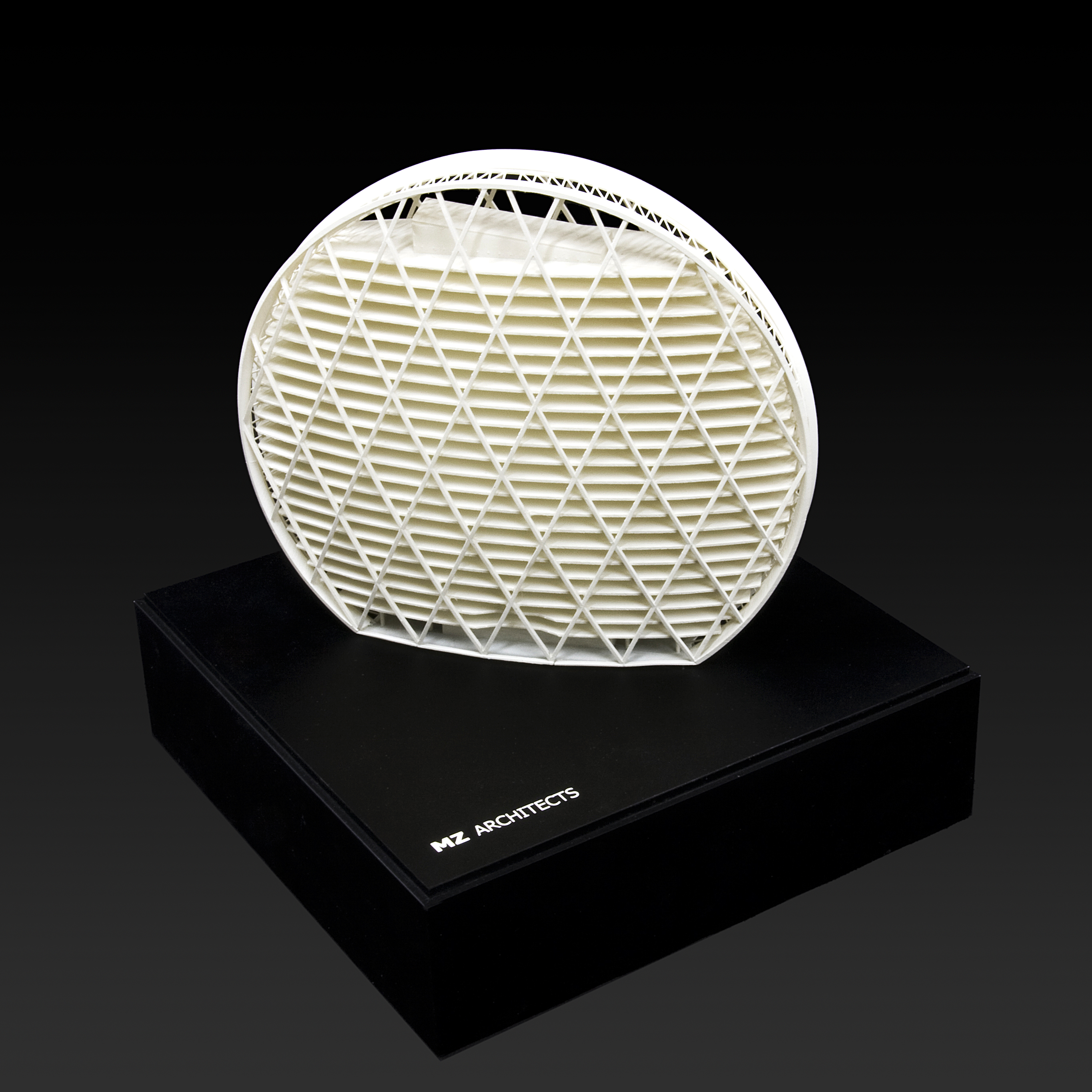

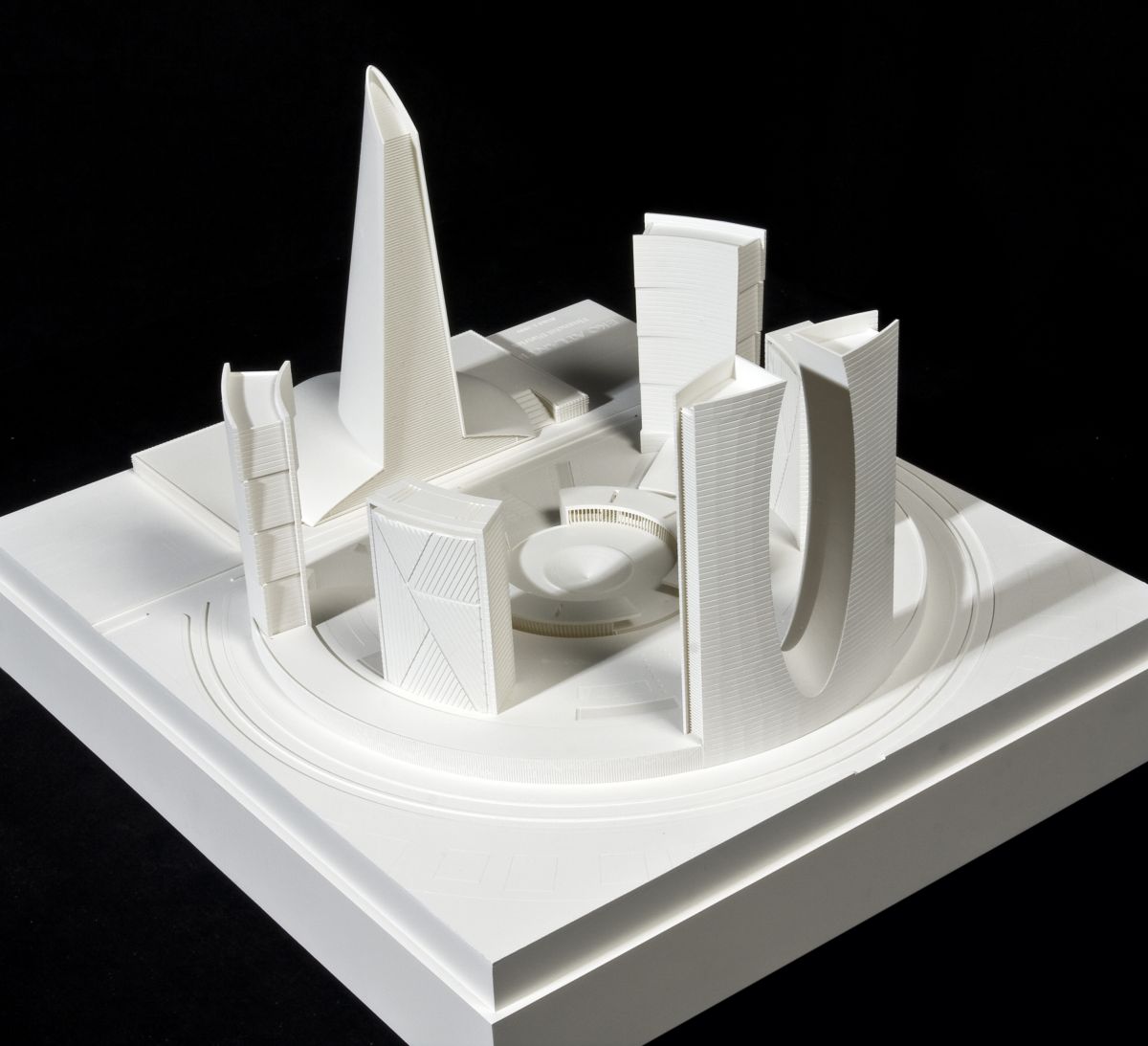

3D PRINTING

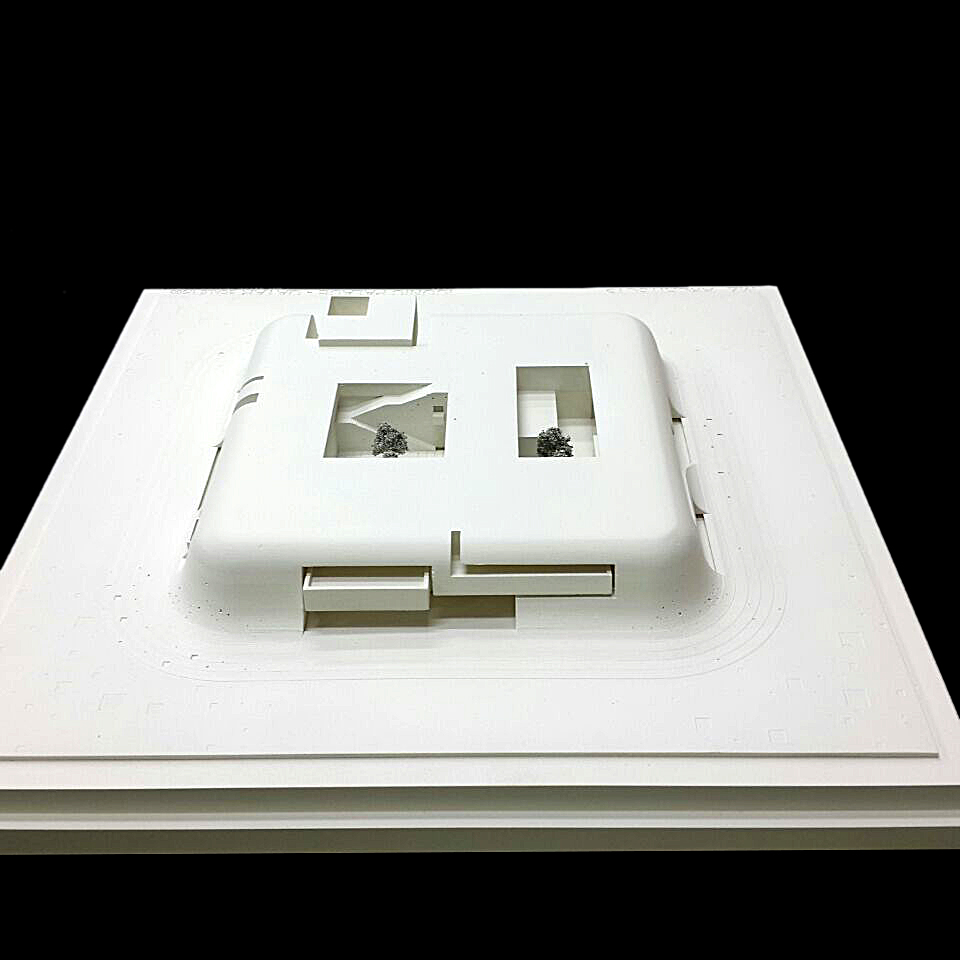

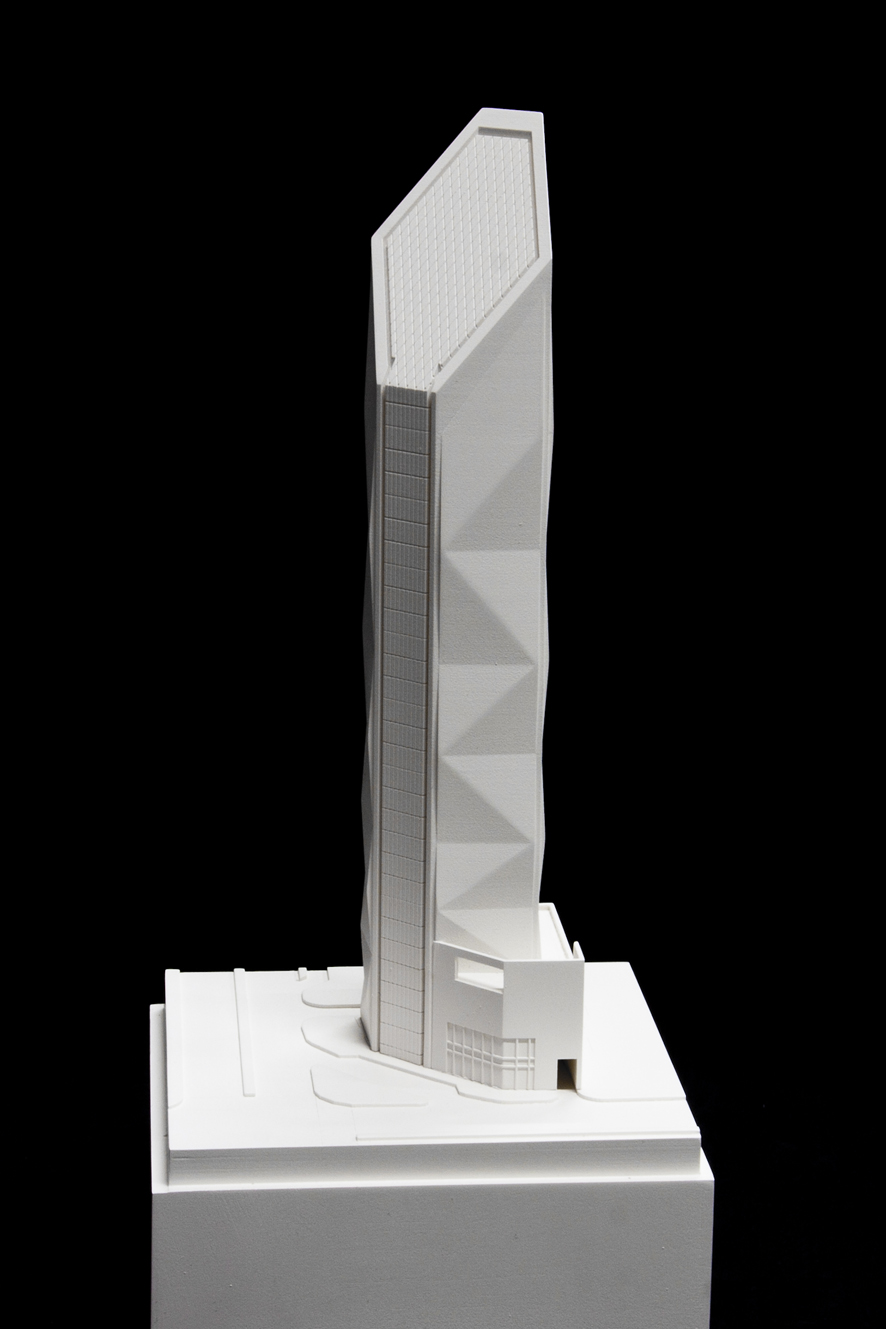

A2MSTUDIO is the first in the Middle East to integrate the new stereo lithography (SLA) technology of machineries to model making to show the maximum details possible in a very clean finishing. The technique leads to a high resolution finishing with more details than all previous available technologies. A thickness of 0.4mm wall and recessed elements of 0.15mm may be reached. The building may be executed in one piece without any use of glue.

Durability:

- Plastic resistant to high temperature;

- No distortion;

- More rigid element.

Quality:

- One piece building;

- No use of glue;

- Highly improved finishing and high resolution details.

Precision:

- Precision of 0.15mm for recessed elements and grooves and 0.4mm for items like walls;

- A 1/500 scale volume with details such as cornice, mashrabiya, handrails and pergolas would cost the same as done without the tiny details when not applicable by model makers;

- Smaller scale details can be reached that model makers cannot execute with regular techniques;

- Any complicated shape can be executed whatever the difficulty.

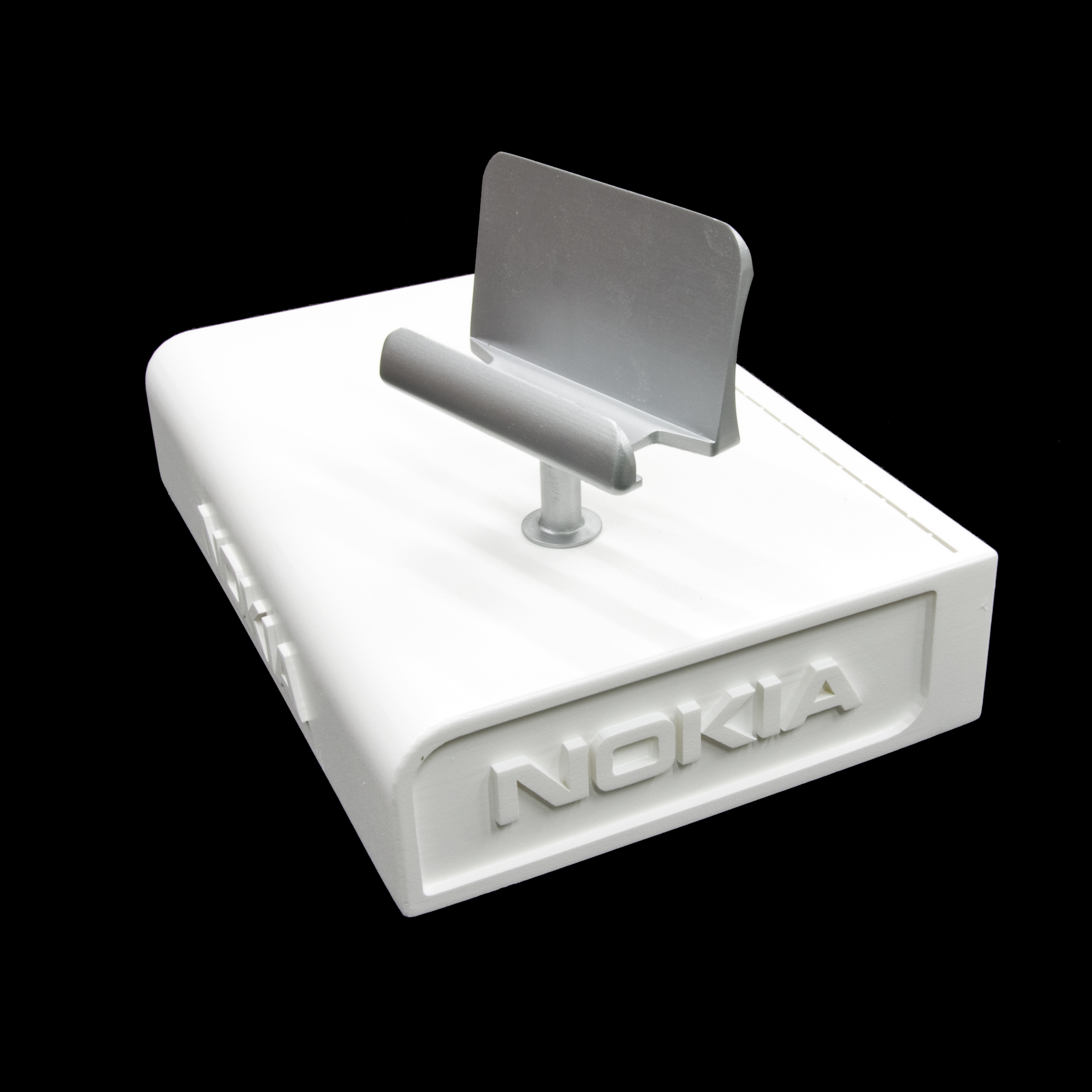

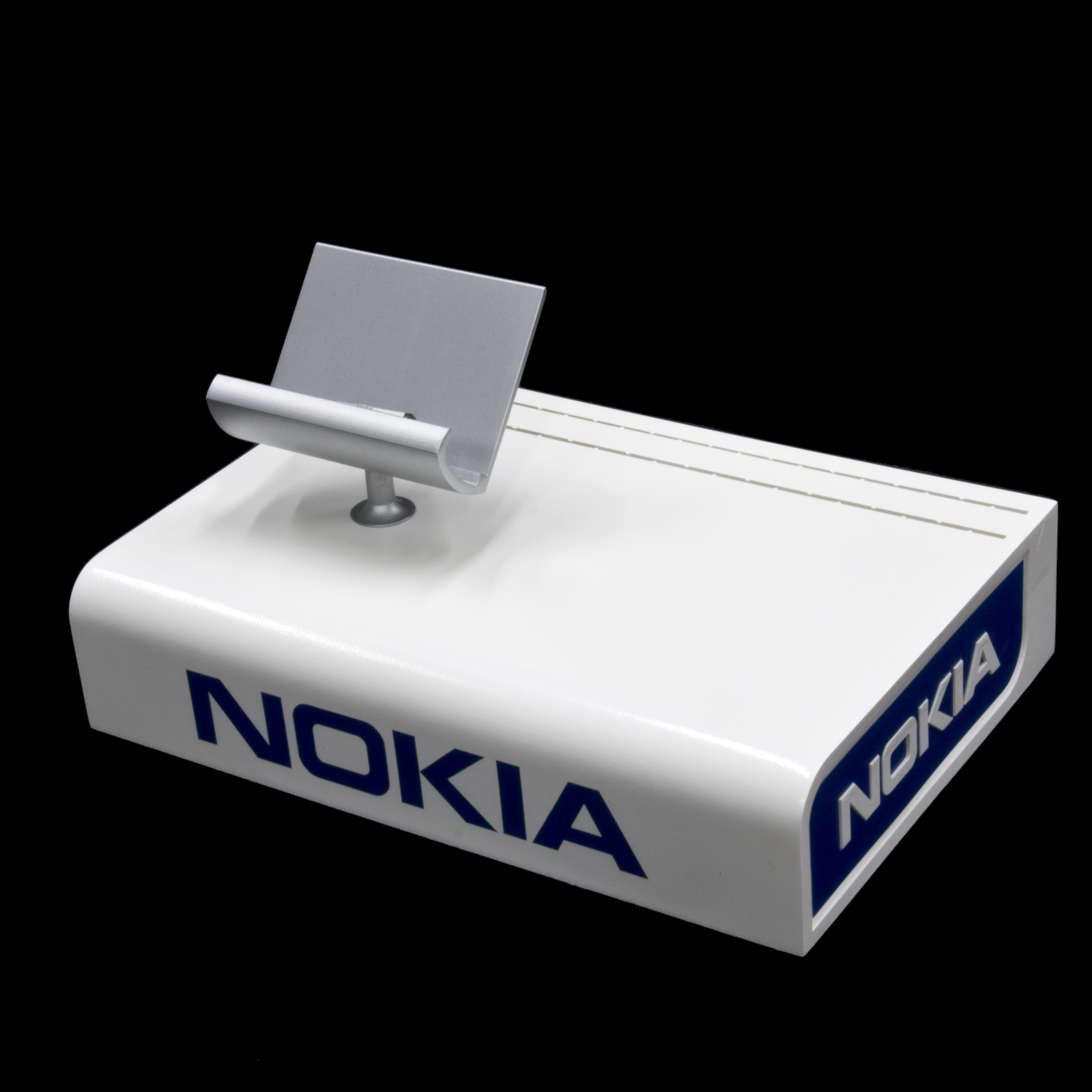

A2MSTUDIO has also integrated to its 3d printing machinery the ProJet 660pro which is the most efficient large-build, full-color 3D printer of its class on the market with a net Build Area of 254 x 381 x 203 mm.

Projet 660pro Benefits

Uniquely Full Color:

- Produce realistic or vivid color models in one step;

- Better communicate the look, feel, and style of product designs;

- 3D print text labels, logos, design comments, or images directly onto models;

- A range of options, from monochrome printing to professional quality color;

- Multiple print heads provide the best range of accurate and consistent colors.

Fastest Print Speed:

- 5x-10x faster than all other technologies;

- Output models in hours, not days;

- Build multiple models at the same time;

- Support an entire department with ease.

Photo Gallery

LASER CUTTING

A2MSTUDIO uses “Universal” laser cutting machines made in USA for cutting and engraving materials with a different thickness such as: Cast and extruded Acrylic, mirrored Acrylic, Cork, Seal press delrin, leather, Mat board, Micro surfaced Plastic, Rubber stamps, Sign vinyl (3mil.), Wood and wood inlay (veneers). It has also the capacity to engrave other materials such as: Anodized Aluminum, painted Brass, Corian, Avonite, Fountainhead, Melamine, Glass, Crystal and Marble.

Both laser systems are compatible with different recommended software programs such as: Graphics programs (Corel Draw, Macromedia freehand), Bitmap/Scanning software (Adobe Photoshop, Adobe Streamline for Raster to Vector conversion), and CAD software (AutoCAD, Design Cad). It has the 3D Effects option to create rubber stamps or produce a 3-Dimensional engraving appearance on other materials.

The Universal X-600 has the power to cut and engrave materials sharply, clearly, and at good depth with a platform size of 81 by 45 cm.

The Universal ILS has the biggest platform size of 122 by 61 cm with a laser power up to 120 watts.